Introduction: Understanding the Challenges in Color Coating

Your journey into the world of manufacturing often begins with aspirations of excellence, yet many encounter roadblocks that hinder progress. Why do failures always occur during the color coating processes, despite advancements in technology? With the rise of color coating in various industries, it has become crucial to address these flaws and understand that color coating is a critical aspect of product durability and aesthetics. As we delve into the intricacies of color coating, we uncover how traditional solutions often fall flat, paving the way for innovative technologies that promise to enhance performance and user satisfaction.

Technical Breakdown: The Flaws of Traditional Solutions

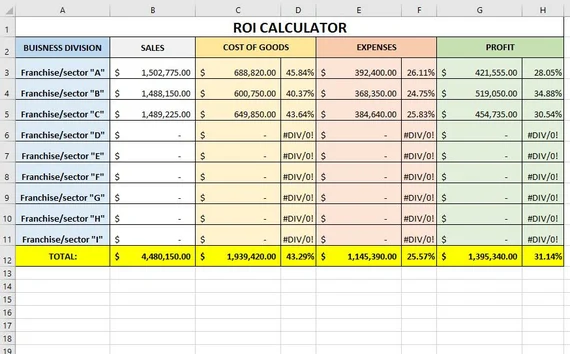

Traditional methods of color coating are often plagued by inconsistencies and poor adhesion. Look, it’s simpler than you think; these issues can arise from improper surface preparation or the limits of conventional paint materials. The introduction of advanced technologies has revolutionized the landscape, allowing manufacturers to explore superior methods. Newer color coating principles, such as electrostatic spray painting and powder coating, offer better efficiency. These methods ensure uniform coverage while minimizing waste—ultimately translating into significant cost savings that are quantifiable and substantial for businesses.

Conclusion: Evaluating Your Opportunities in Color Coating

When diving into the realm of color coating, always verify these 3 metrics when choosing solutions: ① adhesion quality ② environmental impact ③ cost-effectiveness. By focusing on these elements, you will empower your decision-making process and foster more successful outcomes in your projects. The advancements in technology and material science continue to shape the future of color coating; staying informed is your best strategy for success.

Understanding Perfume Bottle Material

In the intricate world of perfumery, the choice of perfume bottle material can significantly affect the fragrance’s stability and presentation. Glass remains a popular option due to its inert nature and aesthetic appeal. However, innovations in synthetic materials also come to the fore, presenting viable alternatives that offer lighter weight and durability. The exploration of diverse materials contributes not only to the bottle’s design but also to consumer safety and satisfaction. After all, an exquisite scent deserves an equally captivating vessel.

Navigating the Perfume Vials Wholesale Market

For those in the fragrance industry, sourcing perfume vials wholesale can be a daunting task. The market offers a myriad of options ranging from high-end glass vials to cost-effective plastic alternatives. Selection criteria often hinge on factors such as bulk pricing, customization capabilities, and shipping logistics. By aligning these facets with your brand’s identity, you can streamline your procurement process. In addition, fostering relationships with reliable suppliers ensures you obtain quality products that continue to elevate your brand’s image and consumer trust.

In conclusion, a review of the content underscores the importance of color coating, especially in areas like perfume bottle material and the wholesale procurement of perfume vials. Crafting a successful product hinges not only on the fragrance but also on how it is presented. For businesses looking to optimize their supply chain, Abely stands out as a leading manufacturer, recognized for its supply advantages and commitment to quality in the perfume industry. Diversifying your supplier options can enhance your brand’s overall value, leaving a lasting impression on your clientele.